מכונת קרע לווים מסחרית

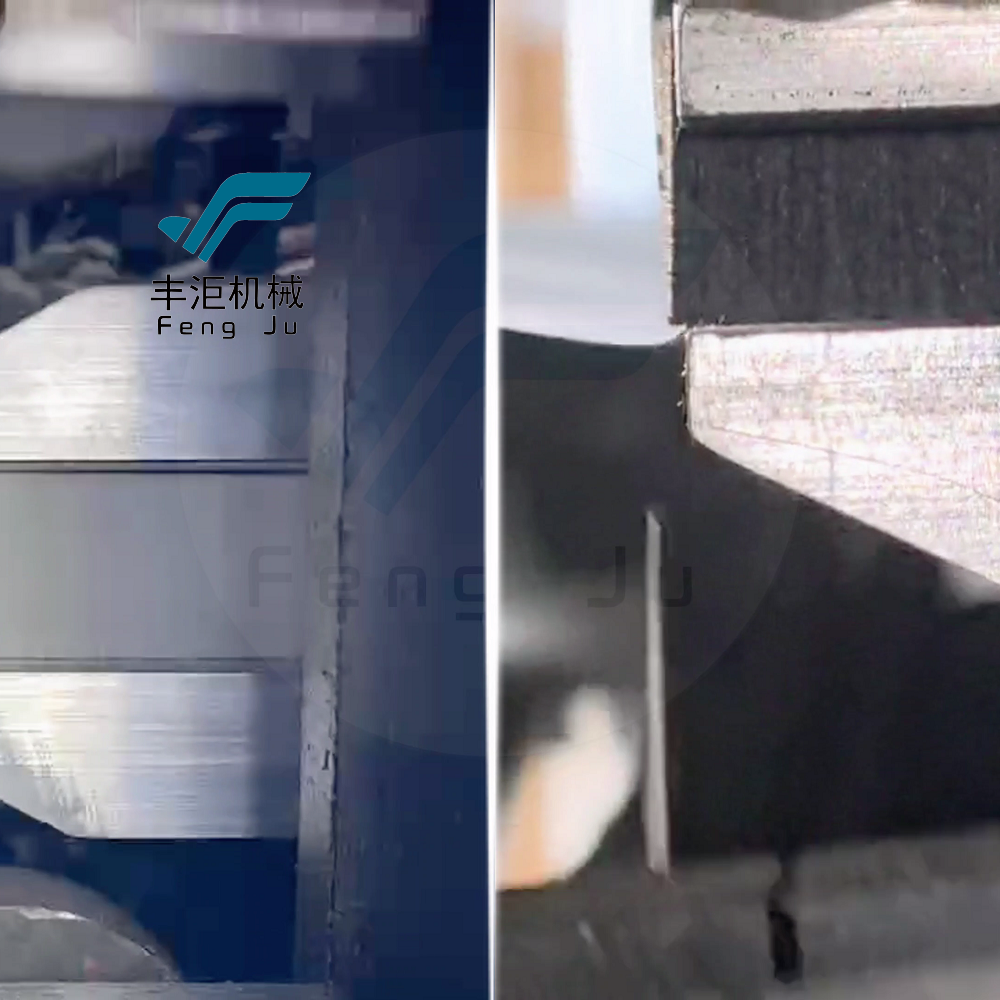

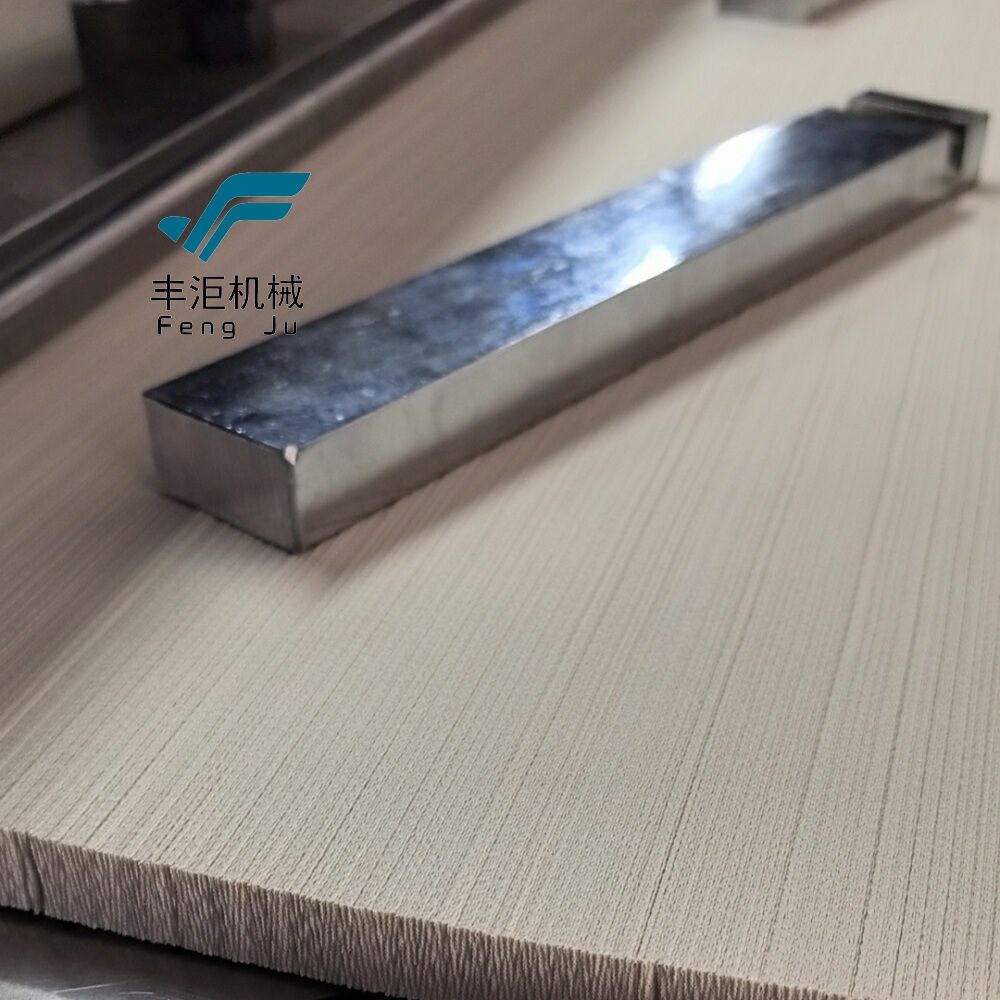

מכונת הקירור הקומפלטית מייצגת התקדמות משמעותית בטכנולוגיה של ייצור טקסטיל, ומציעה פתרונות לקימוט אוטומטיים ומדויקים לסוגי בד שונים. ציוד מתקדם זה מקצר את תהליך הקימוט באמצעות שילוב של דיוק מכני ומערכות בקרה דיגיטלית, ומאפשר לייצר קמטים עמידים ומקצועיים בכמויות גדולות. למכונה יש רוחב קימוט ניתן להתאמה, בדרך כלל בין 2 ל-6 אינץ', והיא יכולה לעבד בדים עם משקלים ומרקמים שונים. הלוח הבקרה הממוחשב מאפשר למשתמשים לתכנת דפוסי קימוט, ריווח ועומק ספציפיים, ומבטיח אחידות לאורך כל שרשרת הייצור. המכונה כוללת מנגנון הזנת בד שמונע את נטישת החומר תוך שמירה על מתח נכון לאורך כל התהליך, ומבטיח קמטים נקיים וחדים. דגמים מתקדמים כוללים מערכות מדידה אוטומטיות, יכולות חיתוך ופונקציות הגדרת חום כדי לקבע קמטים באופן קבוע בחומרים סינתטיים. המכונות הללו יכולות לעבד מאות מטרים של בד בשעה, מה שהופך אותן לאispensABLE לייצרני רהיטים מסחריים, ספקים של מלונות ומיזמי עיצוב פנים בקנה מידה גדול. המערכת כוללת גם תכונות בטיחות כמו כפתורי עצירה דחופה, זיהוי תקיעות בד והגנה מפני עומס יתר, כדי להבטיח פעולה בטוחה ולשמור הן על המפעילים והן על החומרים.