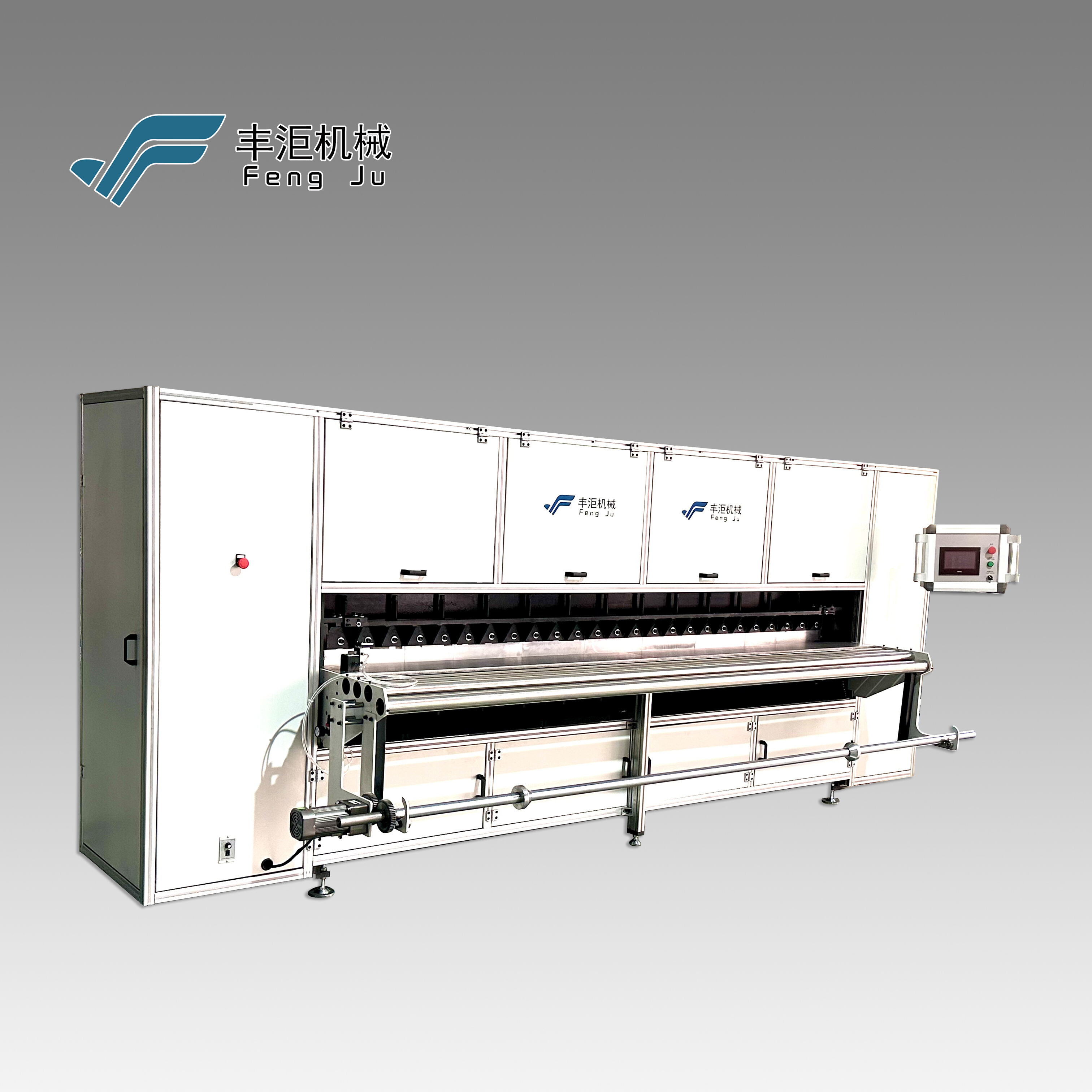

מכונת קפלים אקורדיון

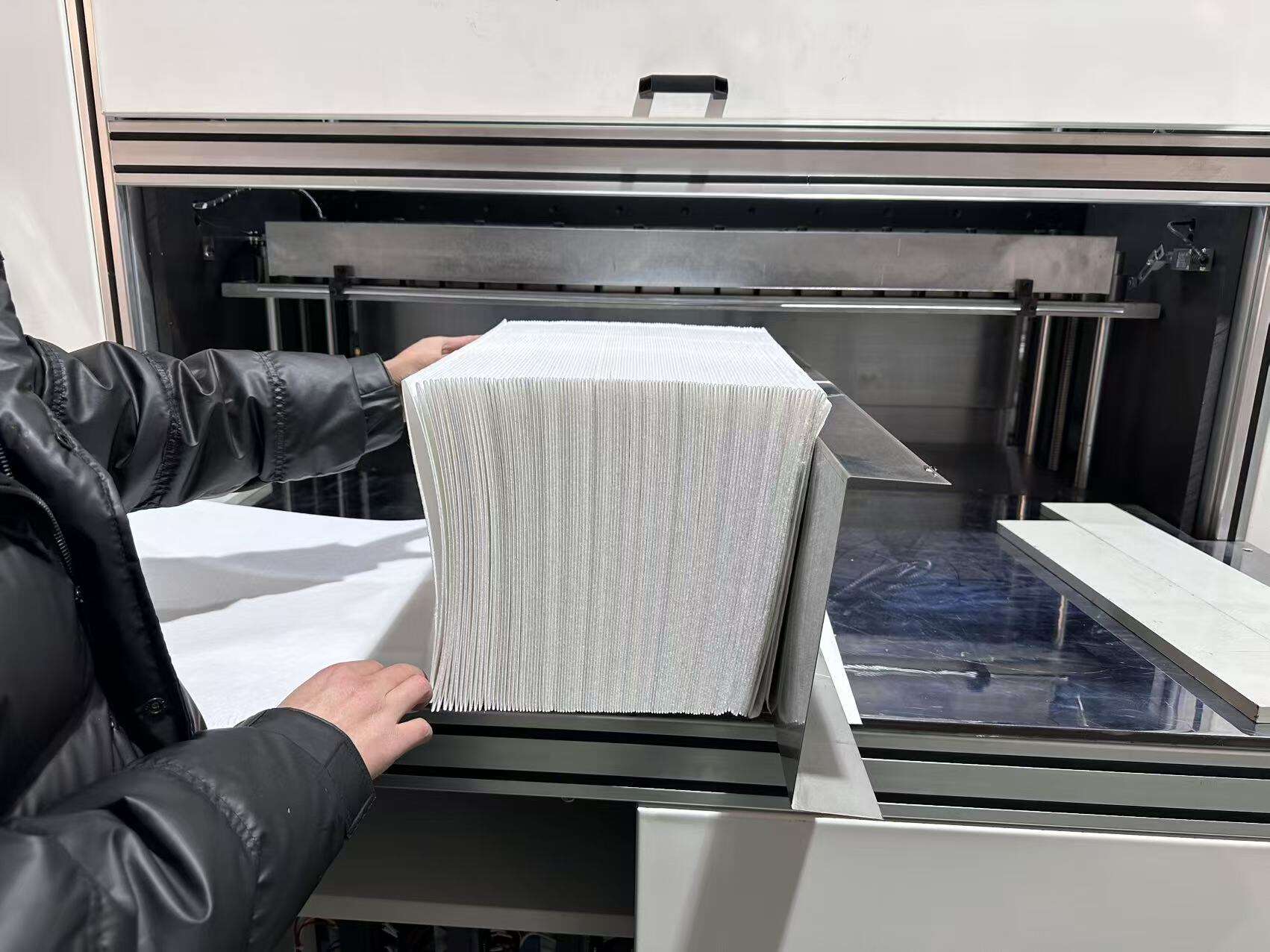

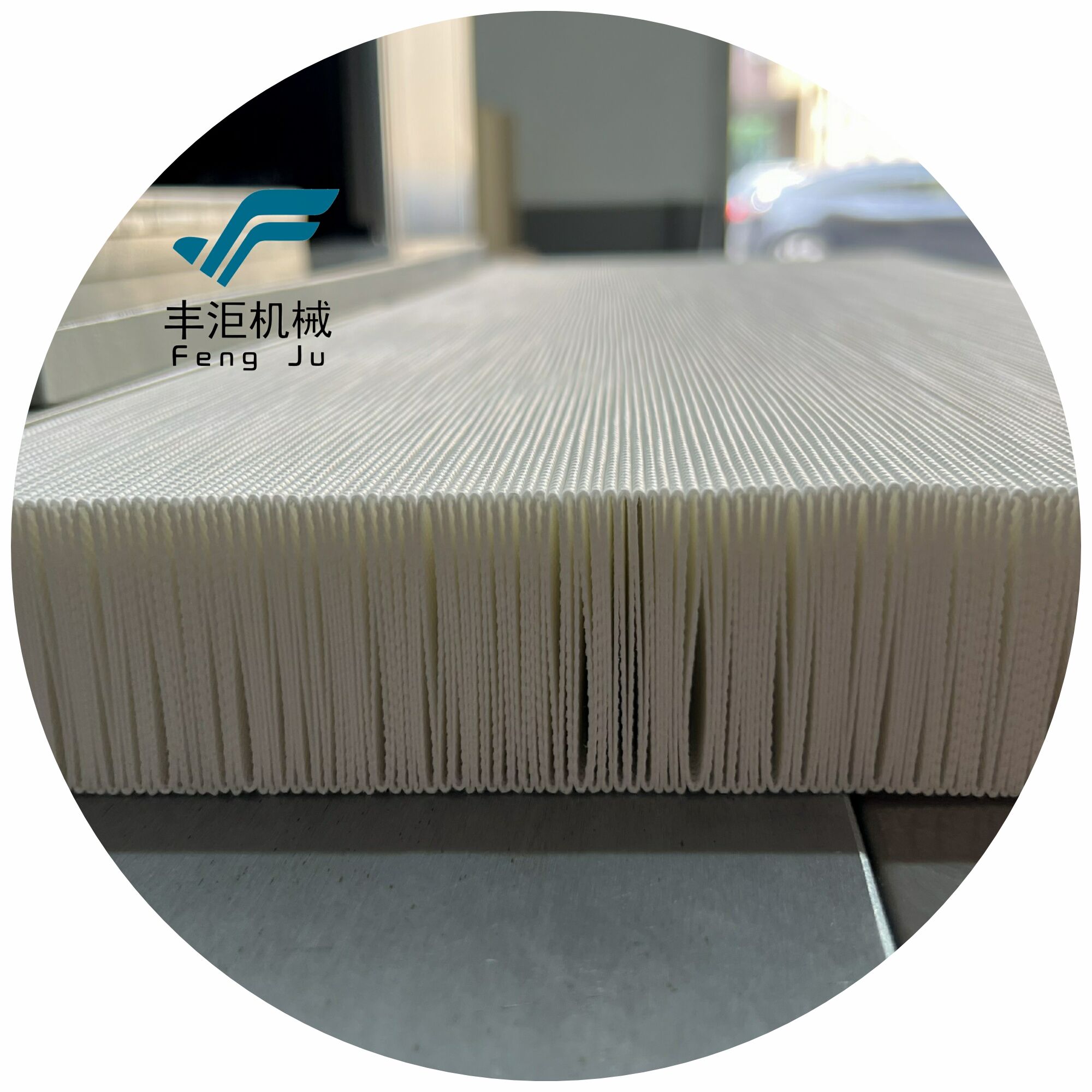

מכונת הקמטים בקפלים מייצגת התקדמות משמעותית בטכנולוגיית ייצור טקסטיל, שתוכננה ליצירת קמטים מדויקים ועקביים בסגנון אקורדיון במגוון חומרי בד. ציוד מתקדם זה משתמש בשילוב של הגדרת חום ודقة מכנית לייצור קמטים אחידים המסוגלים לשמור על צורתם ובנייתם. המכונה פועלת באמצעות תהליך שיטתי שבו הבד מוזן דרך לוחות מיוחדים שיוצרים את דפוס הזיג-זג האופייני תוך שימוש בחום ובלחץ מבוקרים. דגמים מתקדמים כוללים בקרות דיגיטליות להגדרה מדויקת של הטמפרטורה, התאמת מהירות והתאמה אישית של רוחב הקפלים, מה שמאפשר לייצר לפי דרישות מדויקות עבור סוגי בד ו מוצרים סופיים שונים. היכולת הרב-צדדית של המכונה מאפשרת טיפול בחומרים החל מסינטטיים קלי משקל ועד לסיבים טבעיים כבדים יותר, מה שהופך אותה ללאispensable בייצור בגדי אופנה, טקסטיל לבית ויישומים תעשייתיים. פעולתה האוטומטית מבטיחה יצירה עקיבה של קפלים לאורך כל אורך הבד, ומצמצמת בצורה ניכרת את הזמן והעבודה שנדרשו בעבר בתהליכי קימוט ידניים. מכונות קימוט באקורדיון מודרניות כוללות גם תכונות בטיחות ומערכות חסכוניות באנרגיה, מה שעושה אותן מעשיות וכלכליות לשימוש בקנה מידה ייצור מגוון.