εργοστάσιο πτυχωτής οθόνης πόρτας

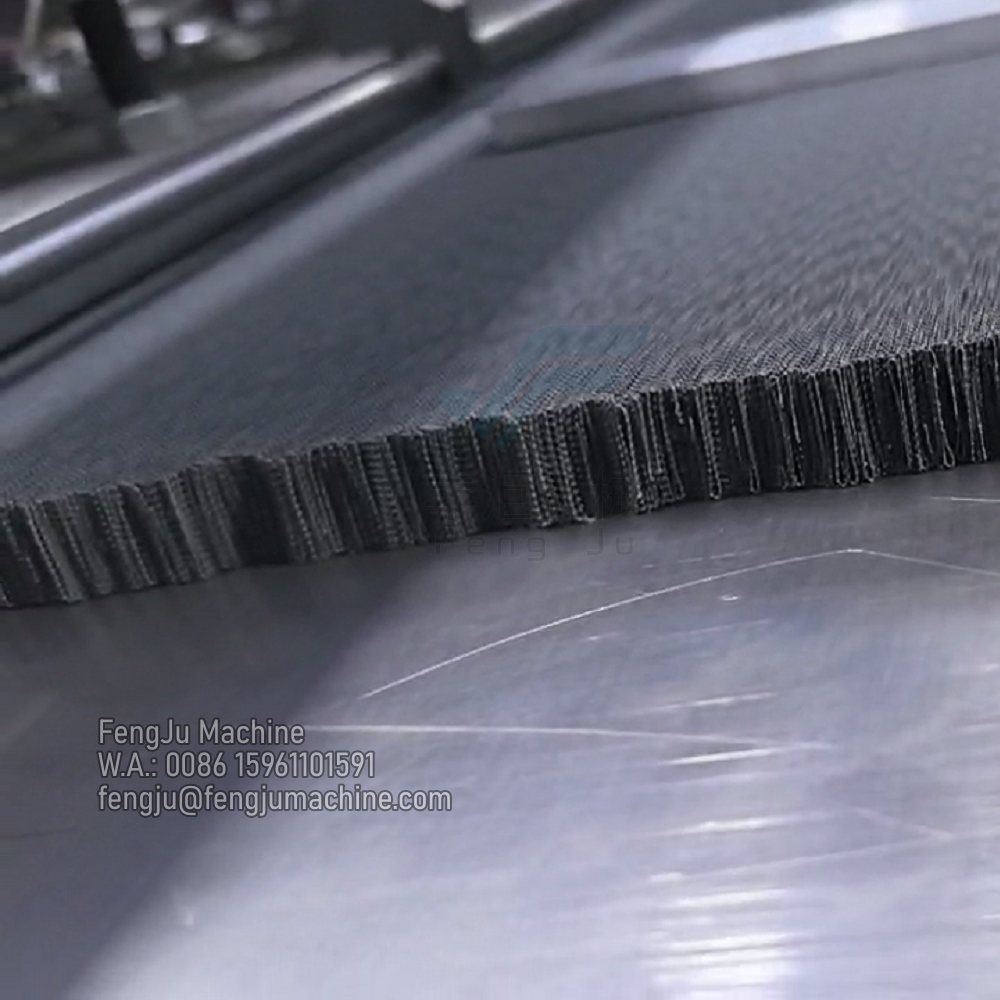

Ένα εργοστάσιο πλισέ πόρτας αντιπροσωπεύει μια εγκατάσταση τεχνολογίας αιχμής, αφιερωμένη στην παραγωγή υψηλής ποιότητας ανασυρόμενων πλέγματος φραγμάτων για οικιακές και εμπορικές εφαρμογές. Αυτές οι εξειδικευμένες εγκαταστάσεις περιλαμβάνουν προηγμένες γραμμές παραγωγής εξοπλισμένες με ακριβή εργαλεία κοπής, αυτοματοποιημένα μηχανήματα πλισέ και συστήματα ελέγχου ποιότητας για διασφάλιση συνεπούς αριστείας του προϊόντος. Το εργοστάσιο χρησιμοποιεί καινοτόμες διεργασίες παραγωγής για τη δημιουργία ανθεκτικών, ανθεκτικών στις καιρικές συνθήκες οθονών που συνδυάζουν λειτουργικότητα με αισθητική έλξη. Η ροή εργασίας παραγωγής περιλαμβάνει συνήθως επιλογή υλικού, ακριβή μέτρηση και κοπή, αυτοματοποιημένες λειτουργίες πλισέ, συναρμολόγηση πλαισίου και αυστηρές διαδικασίες δοκιμών. Τα σύγχρονα εργοστάσια πλισέ πόρτας χρησιμοποιούν εξειδικευμένη τεχνολογία για προσαρμοσμένες δυνατότητες διαστάσεων, επιτρέποντας να πληρούν διαφορετικές προδιαγραφές πελατών. Οι λειτουργίες της εγκατάστασης περιλαμβάνουν ολόκληρο τον κύκλο παραγωγής, από την επεξεργασία πρώτων υλών μέχρι τη συσκευασία του τελικού προϊόντος, με ενσωματωμένο έλεγχο ποιότητας σε κάθε στάδιο. Οι περιβαλλοντικοί έλεγχοι διατηρούν τις βέλτιστες συνθήκες για τη χειριστική και τη συναρμολόγηση υλικών, ενώ ειδικοί χώροι αποθήκευσης διατηρούν την ακεραιότητα των εξαρτημάτων. Συνήθως ο σχεδιασμός του εργοστασίου περιλαμβάνει αφιερωμένους χώρους για έρευνα και ανάπτυξη, επιτρέποντας συνεχή καινοτομία και βελτίωση προϊόντων. Αυτό το ολοκληρωμένο περιβάλλον παραγωγής διασφαλίζει την παραγωγή αξιόπιστων, μακρόβιων οθονών πλισέ πόρτας που πληρούν διεθνείς προδιαγραφές ποιότητας και τις απαιτήσεις της αγοράς.