dodavatel strojů na pletení flymesh

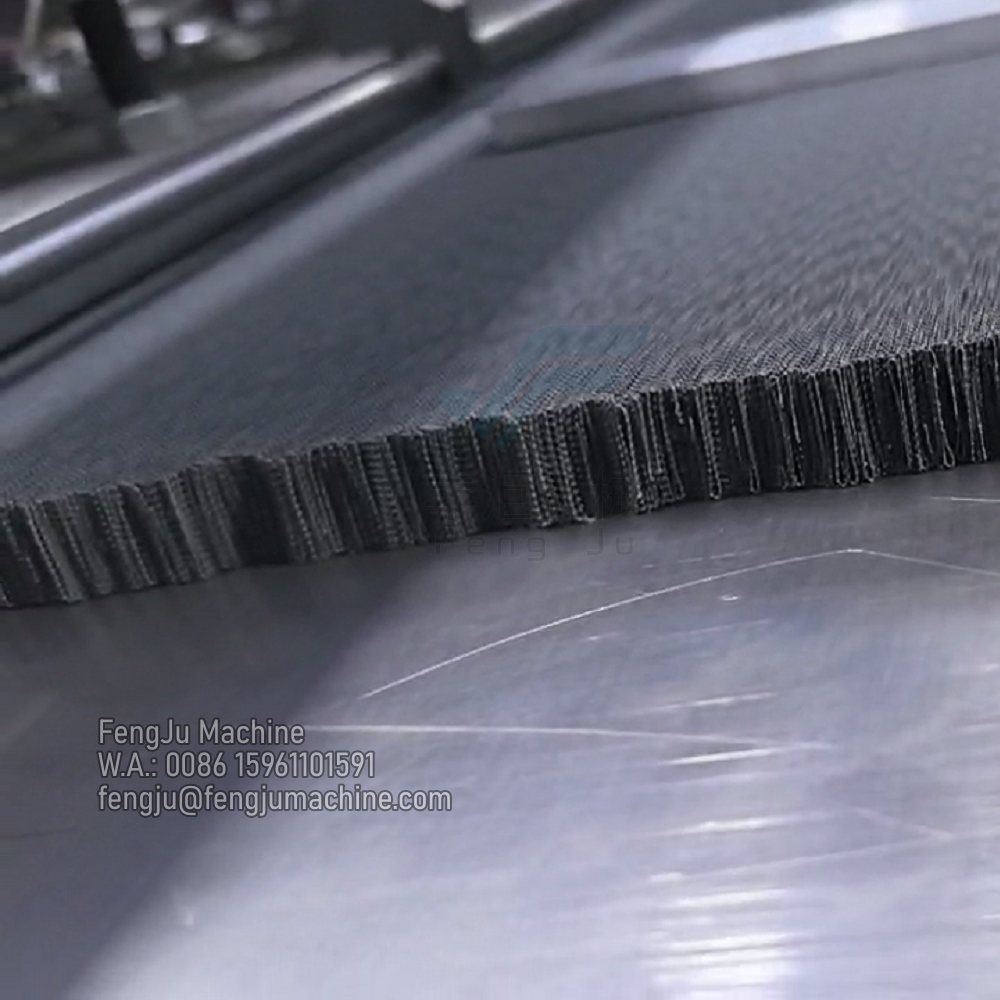

Dodavatel stroje pro základnění flymesh je klíčovým partnerem v odvětví průmyslové filtrace a výroby, nabízí špičkové zařízení navržené pro přesné základnění filtrčních materiálů. Tyto stroje jsou vybaveny pokročilými technologickými funkcemi, jako je automatická regulace hloubky základnění, plynulá regulace rychlosti a inteligentní systémy přívodu materiálu. Dodavatel poskytuje komplexní řešení pro výrobu základněných mřížkových filtrů s vynikající přesností a konzistencí, schopných zpracovávat různé typy mřížkových materiálů – od jemných kovových drátů až po syntetické polymery. Zařízení využívá technologii přesného nařezávání kombinovanou s teplotně řízenými tvářecími procesy, které vytvářejí rovnoměrné základy zachovávající strukturální integritu za různých provozních podmínek. Mezi významné vlastnosti patří digitální ovládací rozhraní pro přesné programování vzorů základnění, automatické systémy řízení tahového napětí materiálu a možnost rychlé změny nastavení pro různé specifikace materiálu. Dodavatel zajistí, že jeho stroje splňují mezinárodní výrobní normy, a zároveň nabízí možnosti přizpůsobení pro konkrétní výrobní požadavky. Tyto systémy jsou navrženy pro nepřetržitý provoz v průmyslovém prostředí, mají robustní konstrukci a vyžadují minimální údržbu. Dodavatel rovněž poskytuje nezbytnou technickou podporu, včetně služeb instalace, školení obsluhy a průběžné pomoci při údržbě, aby bylo zajištěno optimální výkon a dlouhá životnost strojů.