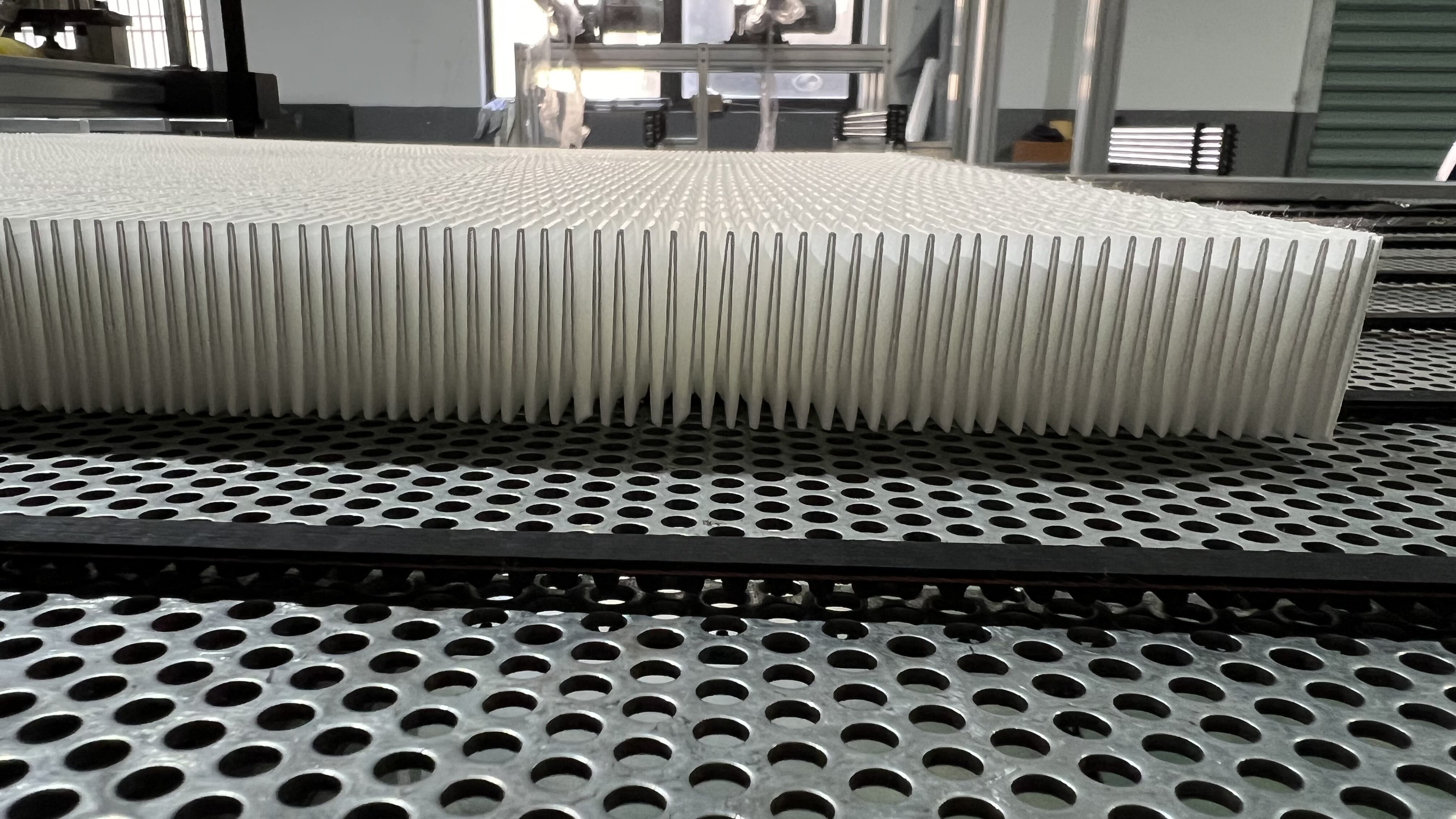

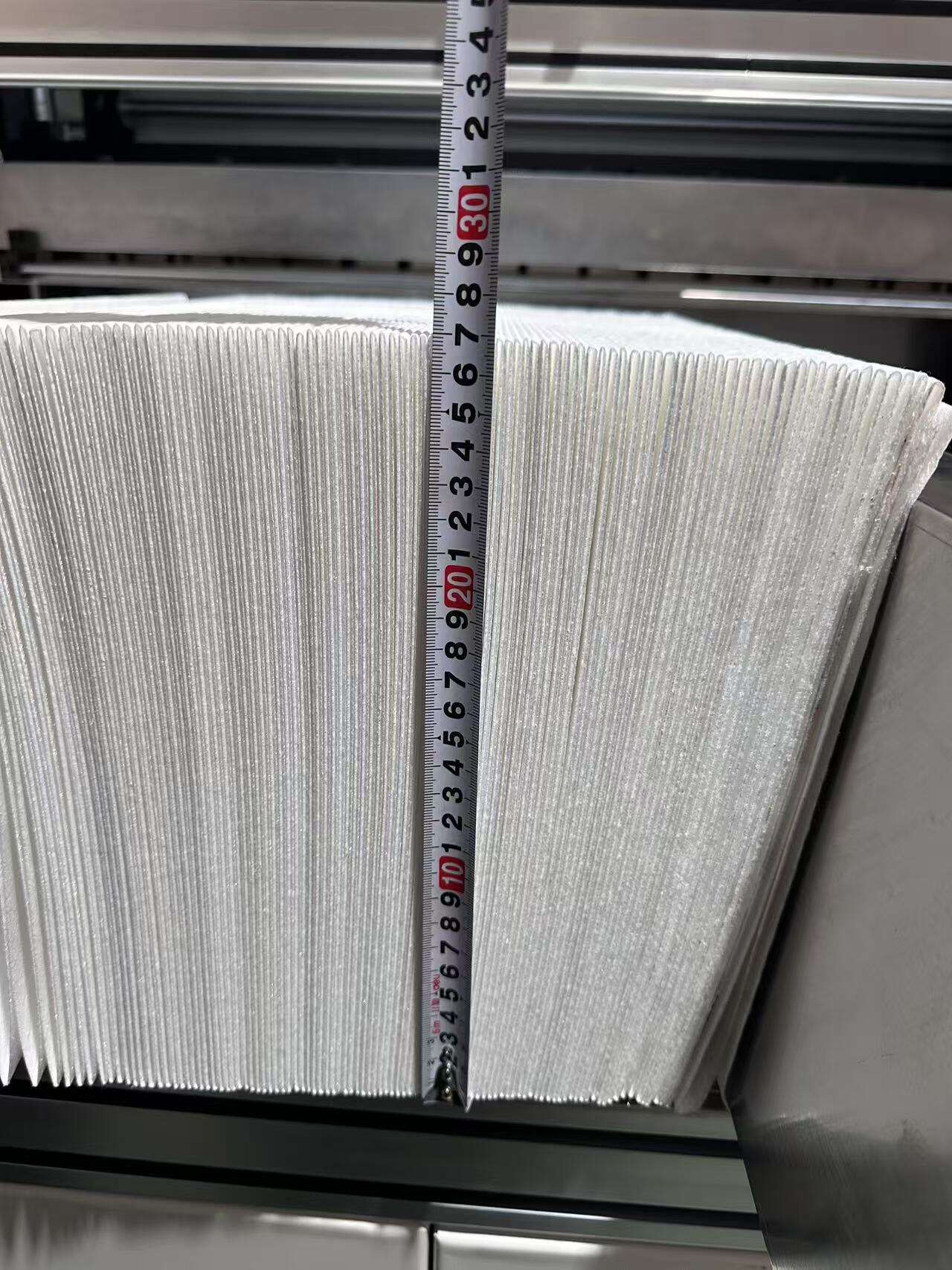

stroj na skládání filtračního papíru

Zařízení na záhybování filtrů představuje významný pokrok ve filtrační technologii, který nabízí přesnost a efektivitu při výrobě záhybovaných filtračních materiálů. Toto sofistikované zařízení automaticky přeměňuje ploché filtrční papíry na rovnoměrné záhybové struktury, které jsou nezbytné pro různé filtrační aplikace. Stroj pracuje prostřednictvím řady synchronizovaných mechanických procesů, včetně podávání papíru, vytváření zářezů, skládání a tvorby záhybů. Jeho pokročilý řídicí systém zajišťuje konzistentní výšku, hloubku a rozteč záhybů, čímž dosahuje optimální filtrační účinnosti. Stroj zvládá různé typy filtračních materiálů, od základního papíru po syntetické kompozity, s možností nastavení parametrů záhybování dle různých specifikací. Moderní zařízení na záhybování filtrů jsou vybavena digitálními ovládacími prvky pro přesná nastavení, která umožňují obsluze upravovat konfiguraci záhybů podle konkrétních požadavků. Technologie zahrnuje automatické systémy řízení napnutí, které udržují stabilitu materiálu během zpracování a tak zabraňují trhání nebo deformaci. Tyto stroje mohou dosahovat rychlosti výroby až několik set záhybů za minutu při zachování vysoké přesnosti a kvalitních norem. Aplikace se vztahují na mnoho odvětví, včetně automobilových vzduchových filtrů, systémů VZT, průmyslového čištění vzduchu a kapalinových filtračních systémů. Univerzálnost těchto strojů je činí neocenitelnými jak ve velkosériové výrobě, tak při vývoji specializovaných filtračních produktů.