pəncərə şəbəkəsi istehsalı maşını

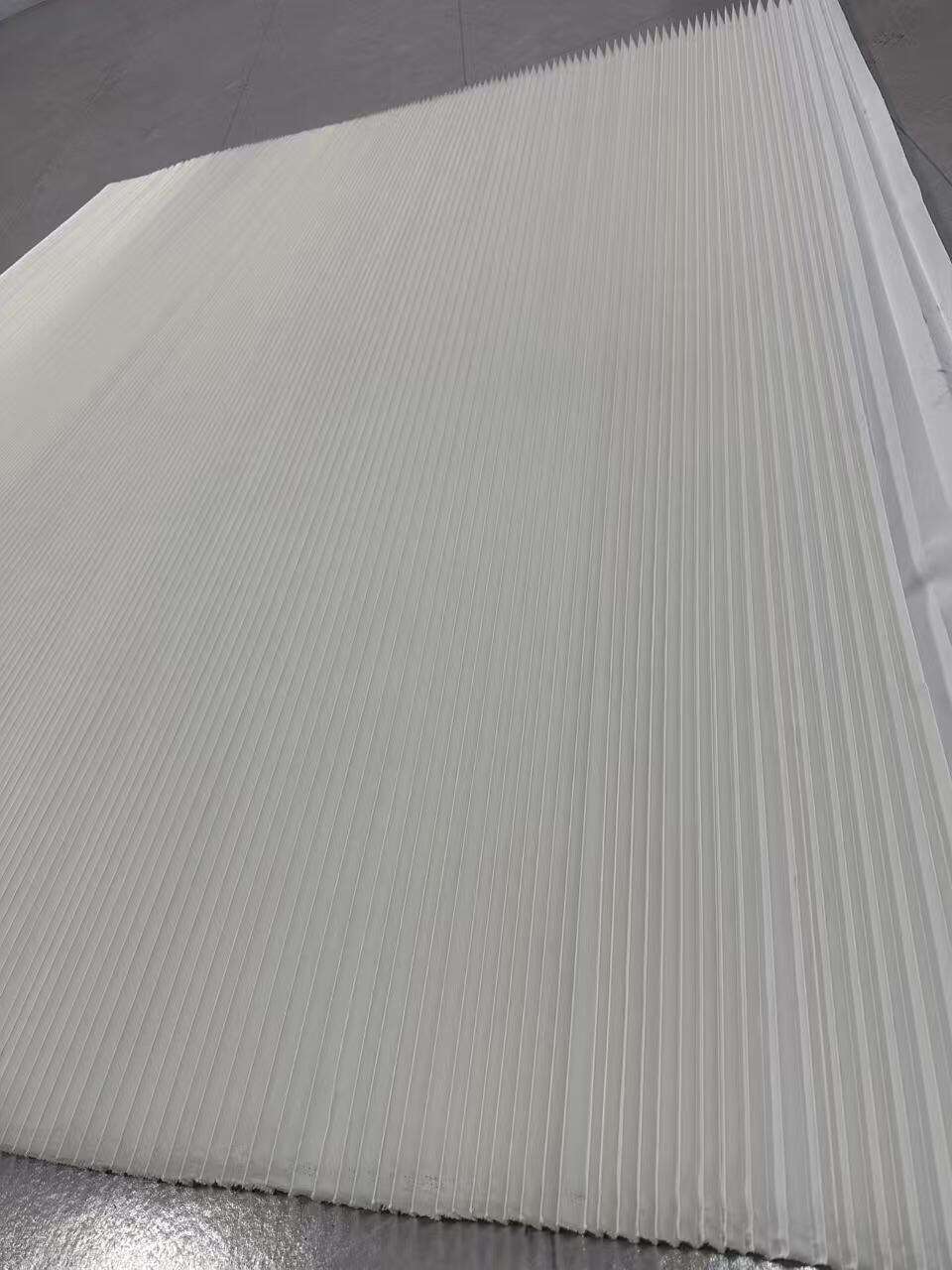

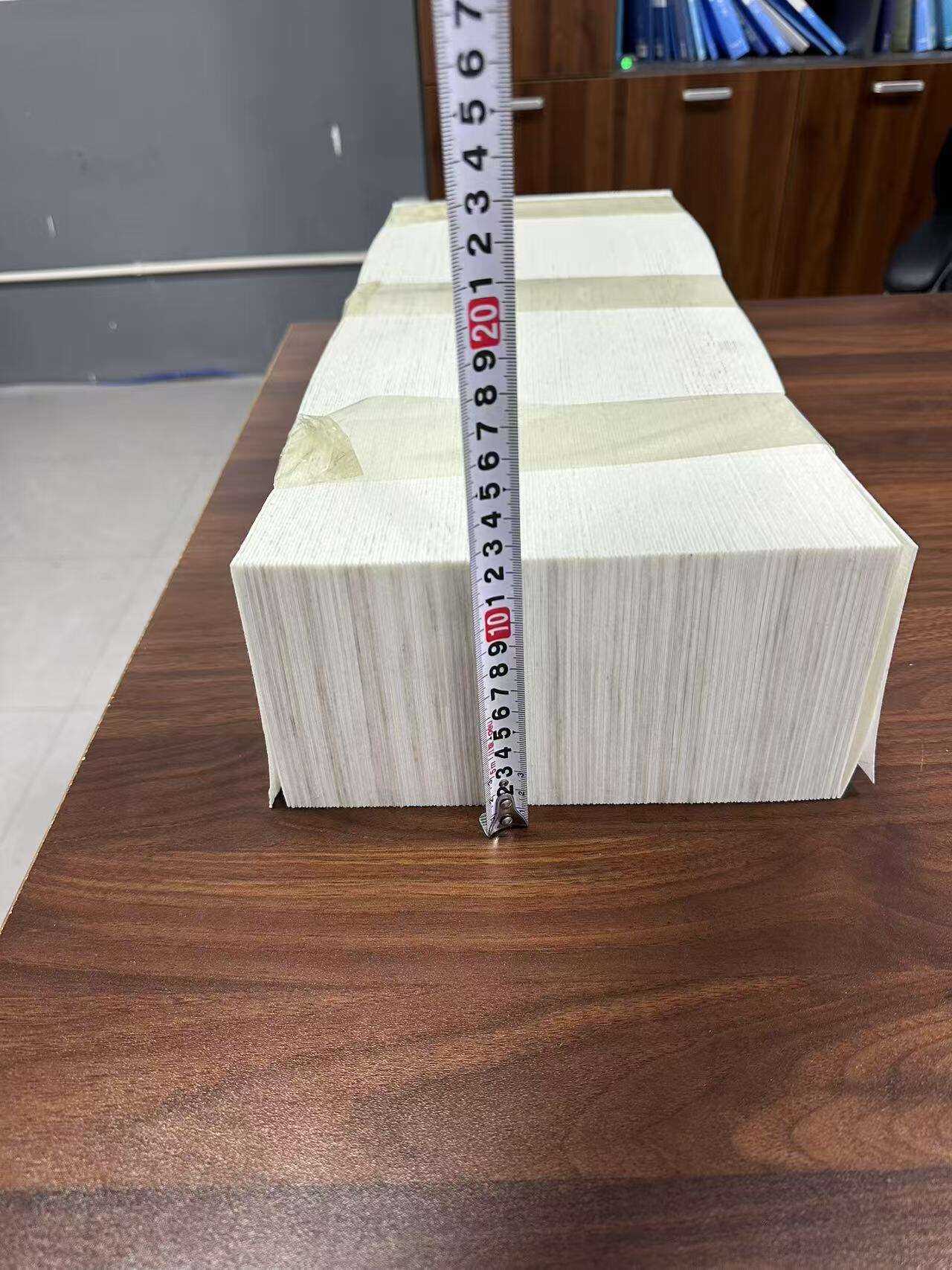

Pəncərədəki hava keçirən toru istehsal etmək üçün nəzərdə tutulmuş maşın, pəncərə və qapılar üçün yüksək keyfiyyətli həşərat töründən qoruyucu tirlərin səmərəli şəkildə hazırlanmasını təmin edən inkişaf etmiş bir istehsal həllidir. Bu irəli səviyyədə avadanlıq dəqiq mühəndislik və avtomatlaşdırılmış prosesləri birləşdirir ki, möhkəm və effektiv hava keçirən tirlər alınasın. Maşın alüminium çərçivələrin kəsilməsi və yığılmasından başlayaraq, tor materiallarının birləşdirilməsi və möhkəmləndirilməsinə qədər bir neçə istehsal mərhələsini idarə edən kompleks sistemə malikdir. İnnovativ dizaynı, torun gərginliyinin ardıcıl olaraq təmin edilməsini imkan verən müasir texnologiyalı gərginlik nəzarəti mexanizmlərini özündə cəmləşdirir, bu zaman avtomatik künc daxil etmə texnologiyası isə çərçivənin mükəmməl şəkildə yığılmasını təmin edir. Maşın şüşə lifi, alüminium və paslanmayan poladdan ibarət müxtəlif tor materiallarını işləyə bilir və bu da onu müxtəlif bazar tələbləri üçün universal hala gətirir. Kompyuterlə idarəetmə sistemi sayəsində operatorlar fərqli ölçülü və modellər üzrə tələbləri asanlıqla tənzimləyə bilir və beləcə istehsal səmərəliliyi maksimum dərəcədə artırılır. Avtomatik gərginlik testi və çərçivənin düzgün yerləşdirilməsinin yoxlanılması kimi daxili keyfiyyət nəzarəti tədbirləri ilə təchiz edilmişdir ki, bu da hər bir məhsulun ciddi keyfiyyət standartlarına cavab verməsini təmin edir. Bu maşın böyük miqyaslı istehsalçılar üçün olduğu qədər orta həcmdə olan müəssisələr üçün də ideal həlldir və tələbatdan asılı olaraq tənzimlənə bilən miqyasda istehsal imkanları təqdim edir.