kajuitfilter plooi-maatsjien

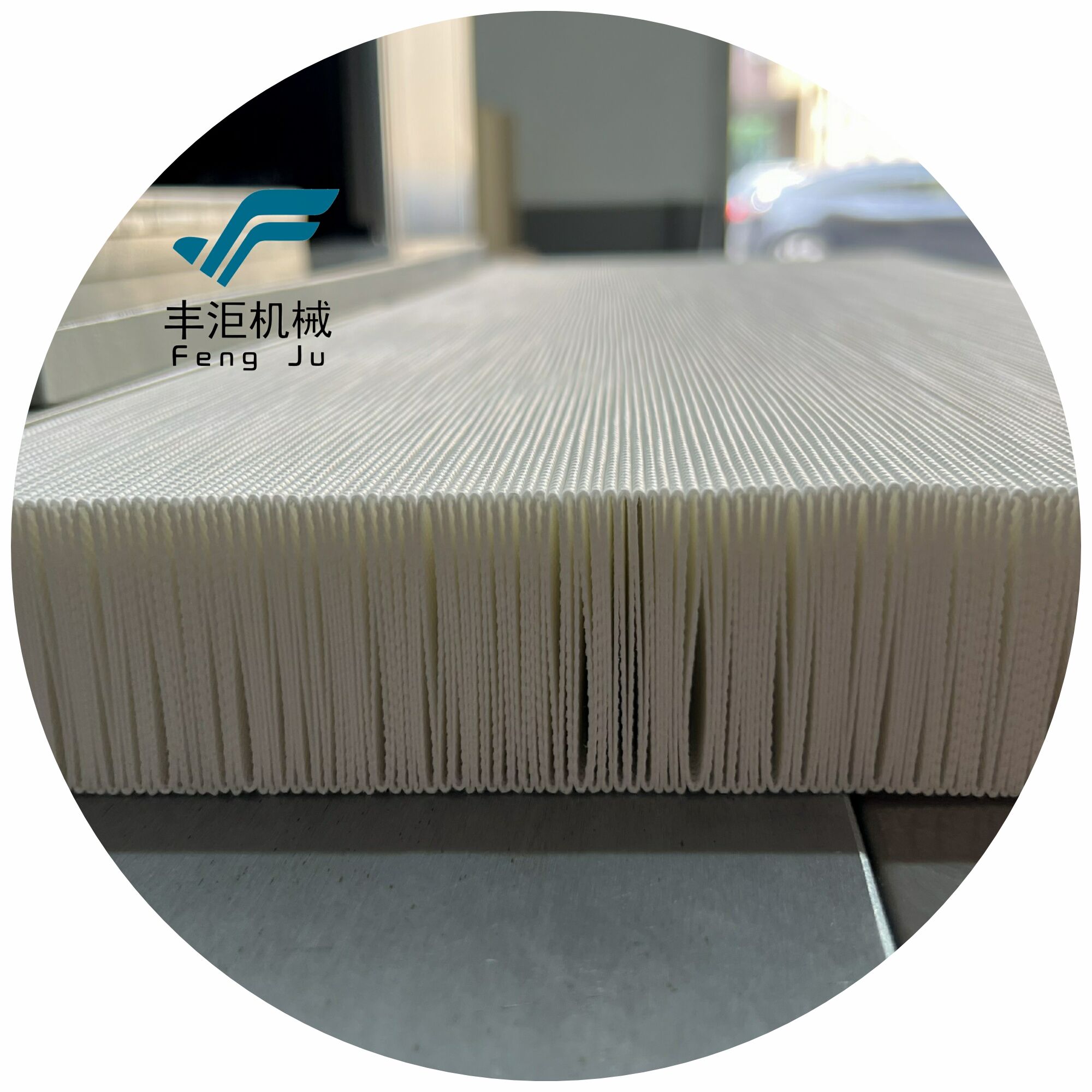

Die kajuitfilter plooi-masjien verteenwoordig 'n toonaangewende oplossing in die vervaardiging van motorfilters. Hierdie gesofistikeerde toerusting verander plat filtermedia in presiese geplooide patrone wat noodsaaklik is vir kajuitlugfilters. Die masjien werk deur middel van 'n kombinasie van meganiese en pneumatoriese sisteme, en handhaaf konstante plooie-hoogte, -diepte en -afstand terwyl dit verskillende filtermateriale verwerk. Die stelsel sluit gevorderde kerfmeganismes in wat presiese voulyne skep, wat eenvormige plooivorming sonder materiaalskade verseker. Dit het geoutomatiseerde voersisteme wat verskillende filtermediabreedtes kan hanteer, gewoonlik tussen 200 mm en 1000 mm, met verstelbare plooiehoogtes van 12 mm tot 50 mm. Die masjien se presisiebeheerstelsel maak produktiesnelhede van tot 80 meter per minuut moontlik terwyl uitstekende akkuraatheid behou word. Temperatuurgekontroleerde verhittingselemente verseker optimale materiaalvoorbehandeling tydens die plooiproses, wat stabiele en duursame plooie lewer. Die integrasie van servomotors en digitale beheerstelsels maak vinnige aanpassings en konstante produksieparameters moontlik. Kwaliteitsmoniteringstelsels, insluitend optiese sensore en spanningsbeheer, verifieer voortdurend plooi-eenheid en materiaaluitlyning. Hierdie tegnologie blyk onskatbaar te wees by die vervaardiging van hoë-doeltreffende kajuitfilters wat voldoen aan stringente motorindustriestandaarde vir lugfiltrering en deeltjievassingsdoeltreffendheid.